Irreversible 230 Vac electromechanical geared motor, equipped with encoder

230 Vac

Up to 5.0 m per door leaf

Control unit that manages the encoder for maximum precision during the automation manoeuvring steps

230 Vac

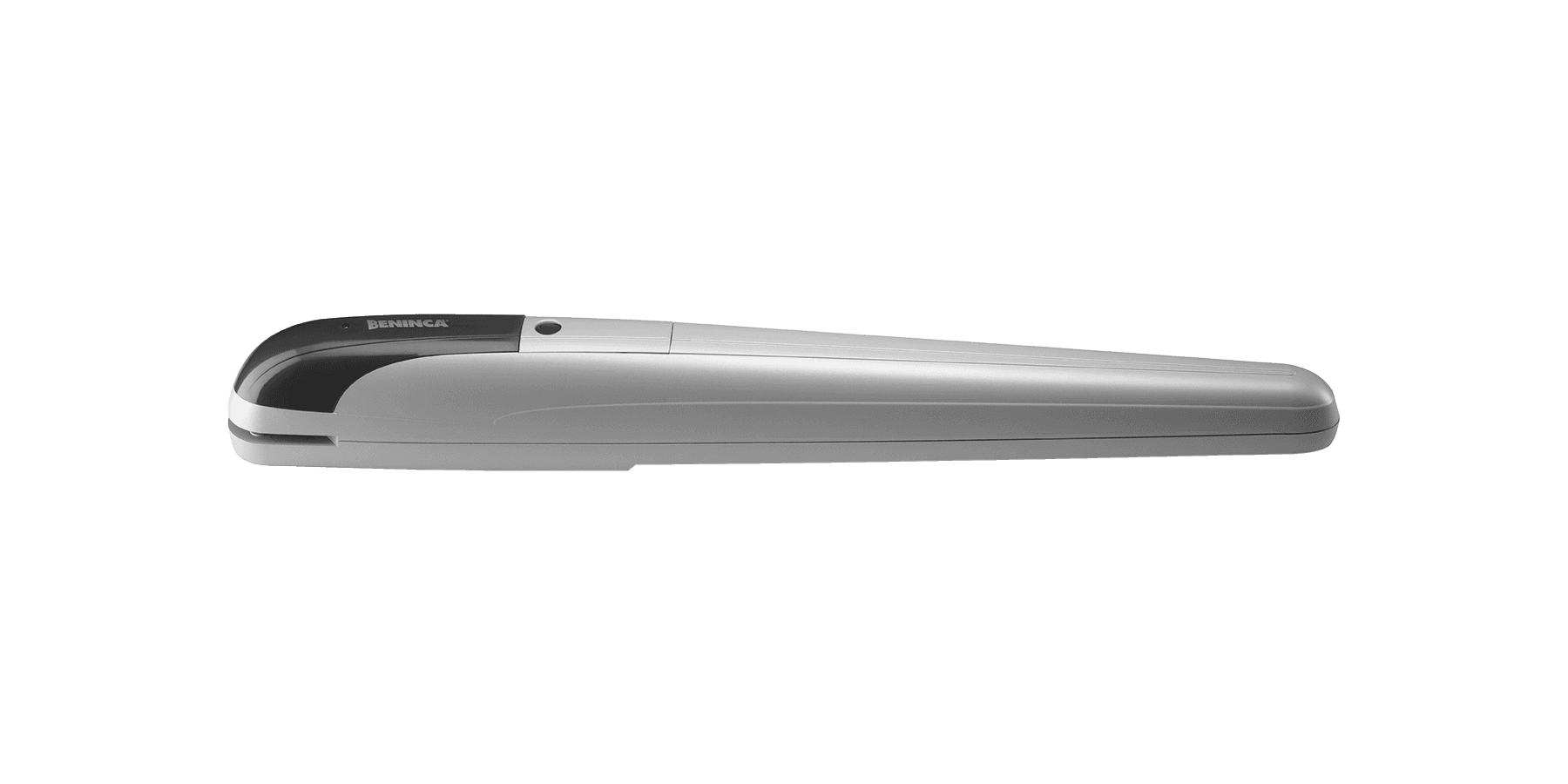

Irreversible 230 Vac electromechanical geared motor, equipped with encoder | The encoder device ensures maximum safety and precision in the gate moving phases | Reliable, quiet, and quick to install geared motor, thanks to its 2 adjustable mechanical stops for opening and closing | Rolled ball screws Ø 20 mm | Easy access release from above

APPLICATION

1 or 2 actuators for swing gates, opposed sliding gates, hydraulic operators, and industrial folding doors

CONTROL UNIT POWER SUPPLY

230 Vac - 50/60 Hz

MOTORS POWER SUPPLY

230 Vac / 600 W + 600 W

MAIN FUNCTIONS

Integrated LCD display | Integrated 433.92 MHz 64-code radio receiver with 3 encoding systems (Advanced Rolling Code, Rolling Code, Fixed Code) | Removable terminal boards | Automatic, semi-automatic and deadman’s logic | Encoder input to detect obstacles | Separate limit switch inputs for each motor | Open, close, pedestrian, step by step and stop inputs | Separate photocell inputs in opening-closing and in closing phases | Input for N.C or 8K2 sensitive edge | Output for electric lock 230 Vac and 12 Vac/dc | Outputs for configuration as gate open indicator, service light, second radio channel and photocell testing | Output for connecting flashing light | Autosetting of operating parameters (with motors equipped with encoder) | Separate electronic torque adjustment for each motor and operating times | Adjustable slow-downs | Advantouch system to configure parameters and manage radio transmitters| Number of maneuvers | Programming access password | Maintenance warning

230 Vac

Control unit that manages the encoder for maximum precision during the automation manoeuvring steps

This function automatically adjusts the operational parameters for simplifying the system�s installation and testing operations

This is used to set the number of cycles after which the required maintenance of the system is signaled

This allows a code to be entered for protection of the control unit programming, to prevent access to menus and modification of parameters

64 transmitters storable inside the receiver

Rukan CitySquare, Jl. Peta Selatan Blok B no. 53-55, Kec. Kalideres, Kota Jakarta Barat, Daerah Khusus Ibukota Jakarta 11840

Phone (021)22520260

Email info@lautanciptakreasi.co.id